HercuLean Structural Foam Cores: Maximize your Inner Strength

and many other applications

Herc™ LLC’s groundbreaking HercuLean™ technology polypropylene foam cores can replace a variety of materials used in boat building, transportation and recreational vehicles, construction, and more. Offering superior performance and versatility, HercuLean foam cores are revolutionizing the way these industries approach material selection and application.

4.9 out of 5 stars from 47 reviews

FEATURES

HercuLean structural foam is strong, light, durable, and easy to process.

It can be cut or routed, easily fitting into standard manufacturing processes. This product is also 3rd Party FMVSS302 certified for Flammability of materials used in the occupant compartments.

Strong & Light

- 10x lighter than wood

- Premier strength to weight ratio

- 5x stronger than wood

Easy to Process

- Drops into manufacturing processes

- Improves application productivity

- Screw and nail retention

Durable & Long Lasting

- 100% waterproof

- Resistant to chemicals

- 3x wood insulation value

- Eliminates concerns about splinters, mold, mildew, rot and insects

- UV stable

- Recycle ready

Versatile structural foam solution for high-strength applications

HercuLean can be used as a stand-alone structural foam or as a core material for laminates to provide a high-strength structure in a variety of applications.

Herc has the capability to provide extruded profiles, planks, and sheet stock in multiple thicknesses and densities, designed to performance specifications required. Herc can produce large, one-piece sheet stock with fabrication equipment for cut-to-size needs, providing our customers with a vast scope of design possibilities.

Material Benefits

HERCULEAN CAN CREATE VALUE IN ALL STANDARD MANUFACTURING PROCESSES

Manufacturing Process | Description | Common Examples | Herculean Advantages |

|---|---|---|---|

Thermoforming | Materials are unrolled or sheets are fed into a heating zone, then molded, and finally cut into individual parts. | Clamshell Food Containers | Most structural material and only domestic supplier |

Adhesive Lamination | One or multiple skin layers on one or two sides are bonded to a core using glues, then pressed, and finally cut into individual composite parts. | Laminate countertops

| Improve material properties, reduce adhesive use by 50% |

Assembly | Separate panels are fixed to a structure, seams are bonded or taped, then finished carpentry can take place such as routing and sawing away excess panel material.

| Exterior Wall Sheathing | Improve material properties, reduce weight by 3-15x |

Thermal Lamination | One or multiple skin layers on two sides are heated under pressure to create a homologous composite with no bond lines, then cut into individual composite parts.

| Honeycomb, Herculean

| The most structural core in the world |

Material Benefits

POLYPROPYLENE-BASED MATERIAL

HercuLean™ is made of polypropylene which allows it to have many structural and performance advantages.

High Flexural Strength

Impact Strength

Fatigue Resistance

Electrical Resistance

Moisture Resistance

High Melt Point

Chemical Resistance

Material Properties

HercuLean is made of polypropylene, which allows it to have many structural and performance advantages.

Lightweight

Mostly air, structural foam material provides strength while reducing weight in the end product.

Moisture Resistant

Resistant to weather, mildew, mold, rot, and insects.

Fits Into Standard Manufacturing Processes

Screw Retention, Nail Retention, Cutting, Routing, Gluing.

Recyclable

Created from recycled materials and is environmentally friendly.

Polypropylene-based Material

A versatile material that provides added benefits such as recyclability, ease of use, compatibility with current processes, and easy to laminate.

Physical Properties - Foam Only

PROPERTIES | TEST METHOD | UNITS | H140 14mm | H220 14mm | H80 19mm | H140 19mm | H220 19mm | H140 25mm |

|---|---|---|---|---|---|---|---|---|

Density | ISO 845 | kg/m3 | 140 | 220 | 80 | 140 | 220 | 140 |

Compression strength

@25% | ASTM D695 | kPa | 1383 | 2299 | 272 | 1250 | 3584 | 1391 |

Compression modulus | ISO 1922 | kPa | 21750 | 33000 | 4200 | 18000 | 58250 | 24200 |

Flexural strength

@ 24°C | ASTM D1037 | kPa | 2335 | 3172 | 1475 | 2459 | 3430 | 1876 |

Screw Retention

#10 Screw | ASTM D1037 | N | 269 | 504 | 135 | 420 | 930 | 546 |

Nail Retention | ASTM D1037 | N | 30 | 51 | 11 | 45 | 121 | 60 |

Flammability | FMVSS 302 | Pass or Fail | Pass | Pass | Pass | Pass | Pass | Pass |

Thermal Conductivity

@ 24°C | ASTM D5930 | W/mK | 0.045 | 0.051 | 0.043 | 0.046 | 0.058 | 0.051 |

R-Value | ASTM D2844 | Per Inch | 3.4 | 2.8 | 3.4 | 3.2 | 2.5 | 2.8 |

Water Absorbtion | ASTM D3575 | kg/m2 | 0.51 | 0.17 | 2.29 | 0.18 | 0.09 | 0.32 |

Panel sizes

HercuLean can be manufactured in a variety of widths and thicknesses. We work with our customers to tailor the specific size needed. Contact us for more information.

product

Herc LLC’s structural foam products made with HercuLean™ technology

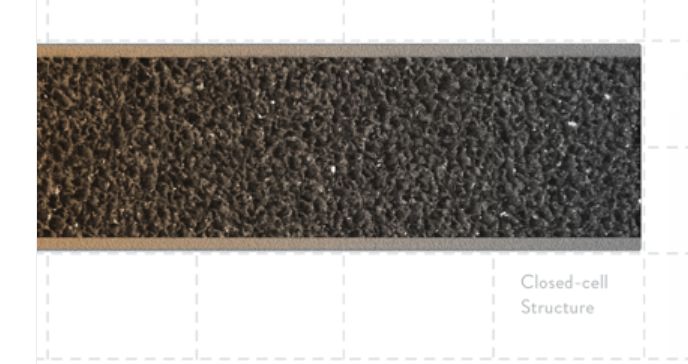

This revolutionary product can inherently withstand common elements that break down wood. Unlike wood, HercuLean closed-cell foam does not splinter and is resistant to ultraviolet rays, moisture, mold, mildew, rot, and insects.